The welding industry is facing a major challenge right now: there are thousands of open welding positions and not enough skilled professionals to fill them (and the demand only continues to rise).

So, what’s the solution?

Career and Technical Education (CTE) programs that prepare students with the hands-on experience employers expect day one.

The strongest CTE welding programs create learning environments that look and feel like professional shops. They train students to confidently step into apprenticeships or entry-level positions with the technical skills and industry-standard practices needed for career success.

Here’s how to design a CTE welding lab that prepares students for future careers:

1. Welding Fixture Tables

At the core of any successful welding program? Teaching students how to set up their work correctly.

Flat shop benches provide a great place to start practicing, but if you really want to give students experience they can apply out in the field, invest in some quality welding fixture tables.

Practicing on welding fixture tables introduces students to the same fixturing techniques they’ll use in professional shops. Engineered for accuracy, their grid of precision holes allows clamps and stops to be secured in place, keeping projects steady, flat and square.

Plus, quality fixture tables also stand up to years of heavy classroom use, maintaining accuracy that programs can rely on for the long term.

If you need help deciding which one is best for your program, read our guide on choosing the right welding table.

2. Prep Stations

It’s important to keep prep work away from the worksurface where students weld.

Why? Well, not only does this mirror the workflow students will see in the industry, but it also improves safety, expands the life of equipment and reinforces that good prep is the foundation of a good weld.

Look for heavy-duty fabrication prep tables that give students a stable place to cut stock, grind edges and prep joints before they strike an arc. The result is cleaner welds and a classroom that runs more like a professional welding workshop.

3. Fixture Tool Kits

You can’t have welding fixture tables without fixture tool kits! After all, the tools are what turn a flat surface into a complete training system.

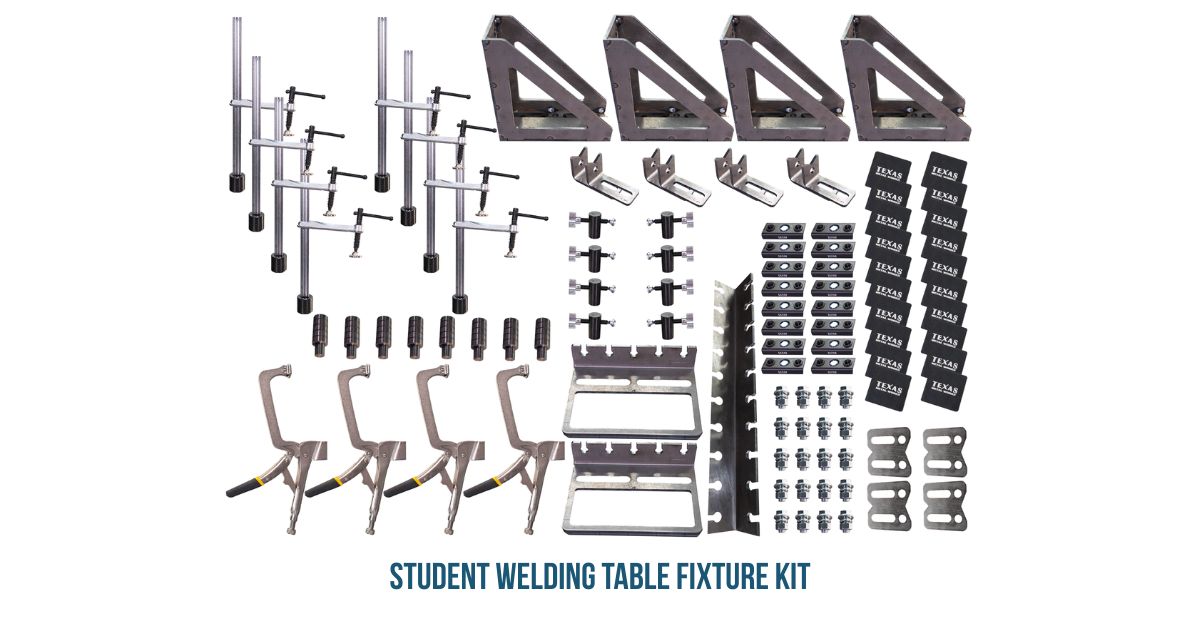

These tools teach students that welding is as much about precision and setup as it is about laying down a bead. In the industry, welders rarely walk up to a piece of metal and strike an arc without first ensuring their work is aligned, square and clamped securely. Fixture kits make that process second nature for students.

Most programs begin with basic student kits that include clamps, stops and squares. These let students practice aligning two pieces of metal, holding them in place and checking that everything is level before welding. It’s a simple exercise, but one that lays the foundation for industry-standard skills. That’s why fixture tool kits are so effective at preparing career-ready welders.

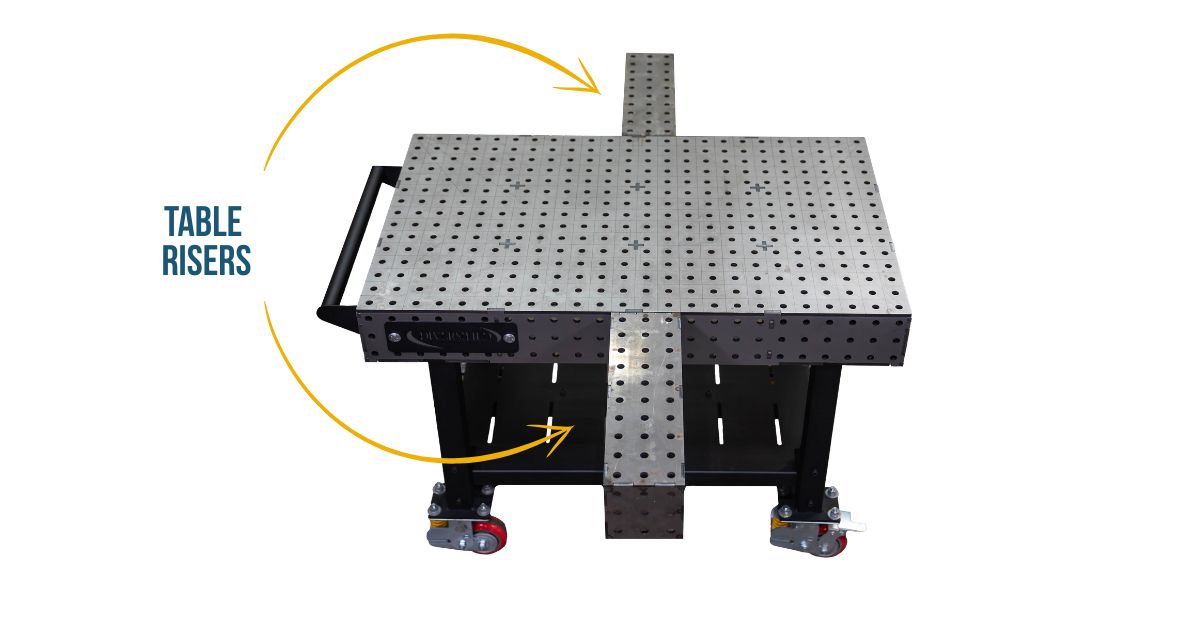

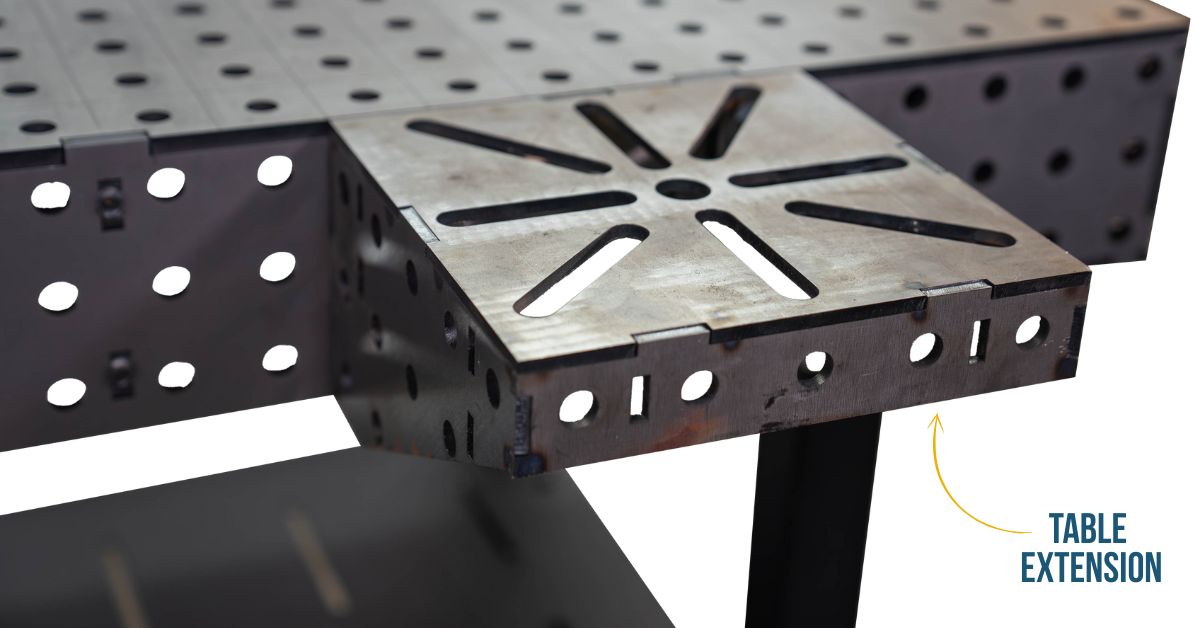

As students advance, programs can introduce more technical kits, like our Advanced Welding Table Fixture Kit, that help teach more professional-level fixture skills. Tools like risers, extensions and v-blocks allow for angled joints, pipe setups and irregular shapes. Students can practice how to secure materials that don’t fit neatly together, which is the kind of challenge they’ll face on the job. Advanced kits also include connectors that make it possible to link multiple tables together or extend a table’s surface for oversized projects.

4. Organized Storage Solutions

Every welding lab should also have a smart storage system in place for keeping a variety of supplies organized and secure.

Metal casework is a durable choice for storing Personal Protective Equipment (PPE), welding rods, wires and tools, while also keeping different metals sorted and ready to use. For even more convenience, tables that have add-on drawer storage, like our Welding Fixture Tables and Fabrication Prep Tables, keep tools and materials within reach while students work on their projects.

5. Safety Equipment and Practices

In a welding lab, students are constantly working with high heat, sparks and fumes, so the environment must reinforce safe habits at every step.

Ventilation and exhaust systems are important to protect air quality and remove fumes at the source. Welding screens or curtains keep sparks and flashes contained, protecting everyone in the room.

Students should also have the proper PPE, including fire-resistant clothing, welding helmets, safety glasses, and leather gloves and boots. Emergency equipment, including eyewash stations and fire extinguishers, should be readily accessible.

6. Individual Welding Bays

All of these elements come together in the welding bay. While it sometimes depends on the program, a well-designed bay typically includes a fixture table for accurate setups, nearby prep space for cutting and grinding, and secure storage for tools and materials. Dividers or curtains create safe boundaries, while local fume extraction combined with proper room ventilation protects air quality.

Just as important, the layout should keep clear sightlines for instructors, making it easy to monitor students, reinforce safe practices and step in quickly if needed.

With everything in one station, students stay focused, instruction flows more smoothly and the lab begins to feel like a professional shop. This approach not only improves safety and organization, but it also helps students develop the independence and accountability they’ll need when they step into apprenticeships or entry-level positions.

7. Multi-Process Learning Opportunities

Today’s welding careers require versatility across multiple processes. The best CTE welding programs expose students to different types of welds, including MIG, TIG, plasma cutting and more.

That requires the right infrastructure: reliable electrical service for multiple welders, secure gas storage and distribution, and safety-first cylinder handling. These details may seem small, but they model the correct handling practices students will need in industry.

8. Effective Demonstration Areas

Central demo stations with good lighting and clear sightlines help instructors model proper techniques for the whole class at once. This saves time, reduces repeated explanations, and gives students a clear baseline before they practice on their own.

These stations should match the equipment students use in their bays, so they can immediately replicate what they’ve just seen. Outfitting demo areas with advanced student kits also allows instructors to show more complex setups, helping students build confidence before trying them independently.

9. Room To Grow

Not every program is going to start with a full shop of equipment (and that’s okay). Many begin with just a few tables and tools to cover the basics. As enrollment grows and projects become more advanced, additional tables, prep stations and storage can be added over time.

That’s why we designed our Core Welding Shop Solution to be modular. Because every table, clamp and accessory kit is part of the same system, schools can build gradually without worrying about compatibility. And when you’re ready to expand further, advanced accessory kits make it possible to link tables together or extend the work surface for larger, more technical projects.

Building a Welding Lab That Lasts

The programs that succeed are the ones that design labs to feel like professional shops. From fixture tables to prep areas, storage, safety and bays, every decision shapes how students learn.

Our team works closely with educators, administrators and dealers to design CTE spaces that balance safety, durability and functionality. We bring that same expertise to welding labs, helping schools create environments that fit their goals, budgets and long-term plans.

If you’d like to see how our Core Welding Shop Solution ties it all together, download our brochure by filling out the form below. It’s a practical starting point for any program looking to build or expand a welding lab the right way.