The best welding programs have one thing in common: their graduates walk into jobs already knowing how to set up work like professionals. While a strong curriculum is a contributing factor, there’s a secret ingredient to making students ready for day one — the welding tables.

For educators, administrators and dealers, choosing the right welding tables is one of the most important (and most overlooked) decisions when building or expanding a welding lab. It’s a choice that impacts how students learn, how instructors teach and how schools protect their long-term investment.

By 2029, the industry is projected to need an additional 320,500 professionals, with about 80,000 welding jobs to be filled every year between 2025 and 2029. Schools that invest in the right foundation give their students — and their programs — a real advantage.

So, how do you choose the right welding table?

Welding Tables vs. Fixture Tables

The term “welding table” gets used loosely, but there’s a big distinction:

Traditional welding tables provide a solid work surface for basic practice, but they create a gap between classroom learning and professional expectations. Most industrial shops use fixture table systems with standardized clamping and setup processes. When students learn on the same equipment they’ll encounter professionally, they graduate job-ready from day one.

Fixture tables transform every project into professional training. Students learn proper setup, squaring, alignment, and fixturing techniques while completing their assignments. This integrated approach to skill development gives your graduates a competitive advantage in the workforce.

For educational programs, we recommend fixture table systems over traditional flat welding tables. The reason is simple: fixture tables prepare students for professional welding environments in ways that flat tables cannot.

Choosing the Right Welding Table for Education

When deciding what’s right for your lab, a few factors rise to the top:

1. Material & Durability

The material of your welding table is the first (and arguably most important) decision you’ll make. Not all metals are created equal, and what works in one environment may not be ideal in another.

- Cast Iron: Known for its stability and long history in industrial shops, cast iron tables are incredibly flat. But they come with two big downsides in a classroom: weight and brittleness. If a corner chips or the table takes a hard strike, cast iron can crack. For schools where equipment is frequently handled by inexperienced welders, that’s a risk. Due to their weight, they’re also extremely hard to move.

- Stainless Steel: Resistant to corrosion and perfect for sterile environments, stainless steel is a premium choice. But it’s overkill (and overpriced) for most classrooms. In fact, it’s often 3 times as much as carbon steel! It’s better suited to food processing or medical labs where hygiene is critical.

- Aluminum: Lightweight and affordable, aluminum works well in hobbyist shops, but it simply doesn’t stand up to sparks, clamping pressure or repeated hammering. Over time, it warps and dents, leaving students with an uneven surface.

- Carbon Steel (A572-50): This is the material most high schools and vocational programs should rely on (and it’s what we use for our tables). Strong, safe and much more forgiving under stress, carbon steel can withstand decades of daily student use. If a table does get stressed, it bends instead of cracking, which is a far safer outcome in a student shop.

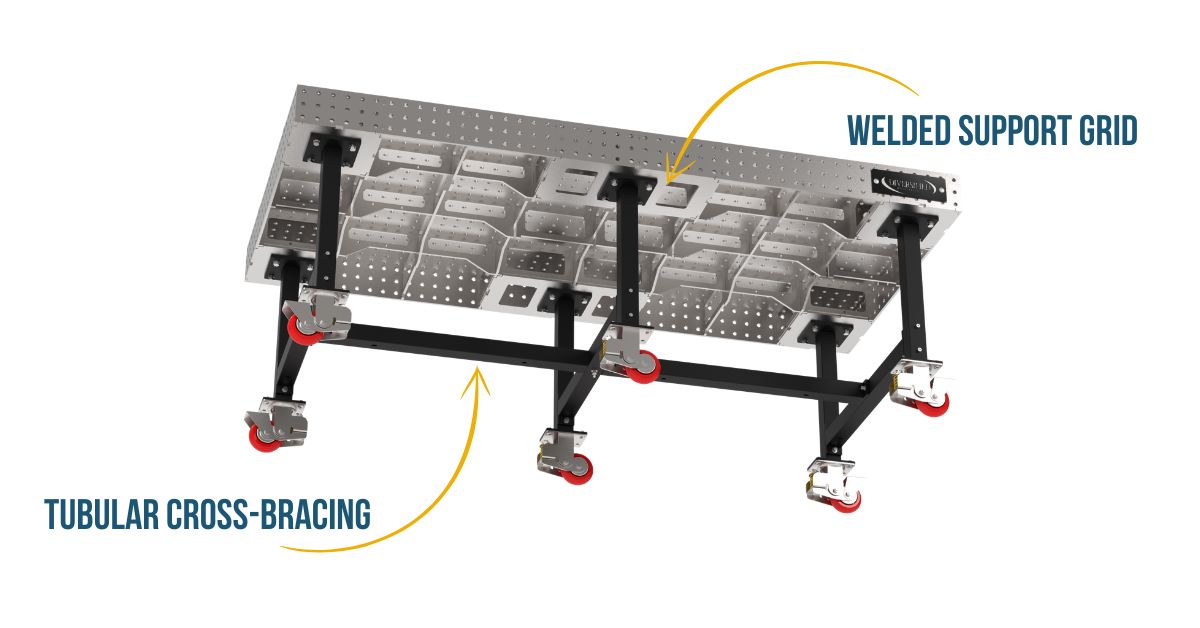

2. Strength & Stability

A welding table is only as strong as its backbone. In classrooms, that means surviving heavy use without wobbling, bending or shifting. The right build – a carbon steel top at least 3/8” thick, reinforced with a welded support grid and tubular cross-bracing – gives the table the strength to handle grinding, hammering and repetitive fixturing.

When made in the USA, those standards are enforced at every stage. The result is welds, frames and grids that are engineered to handle decades of educational use.

3. Surface Flatness

3. Surface Flatness

Accuracy starts with the surface. A table that’s even slightly warped can throw off alignment. Look for welding tables that have flat surfaces, like our Welding Fixture Table’s surface that is leveled to within 0.025” per foot. That precision ensures the table isn’t making students mess up their work. Instead, when a project comes out unevenly, it becomes a learning experience, not a flaw in the foundation.

4. Size, Adjustability and Versatility

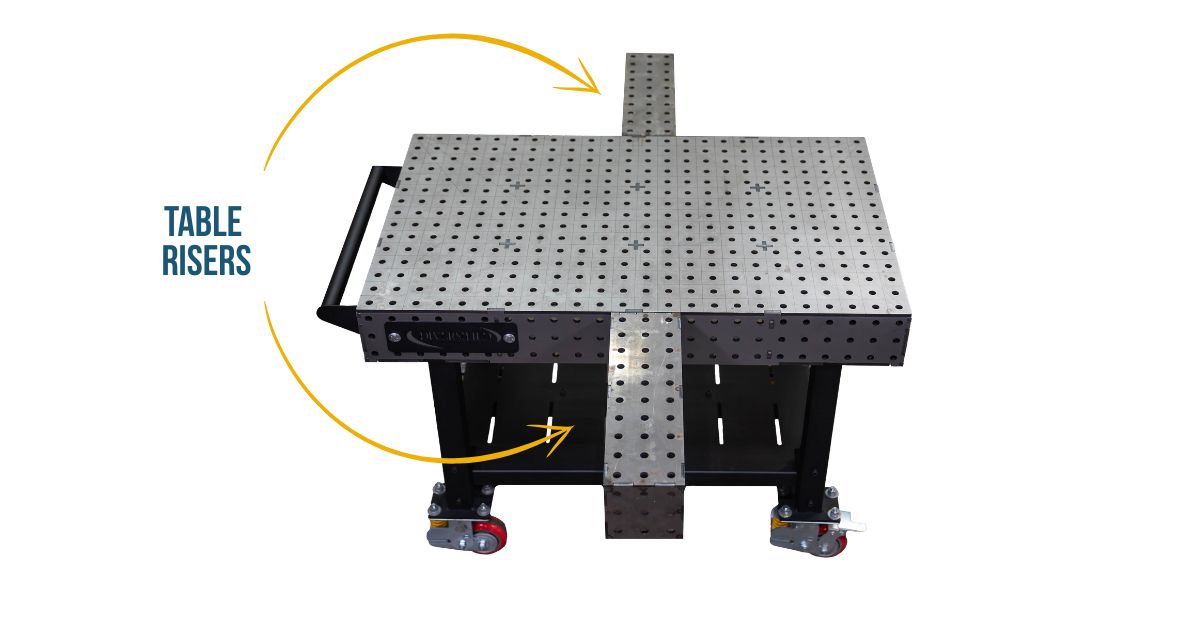

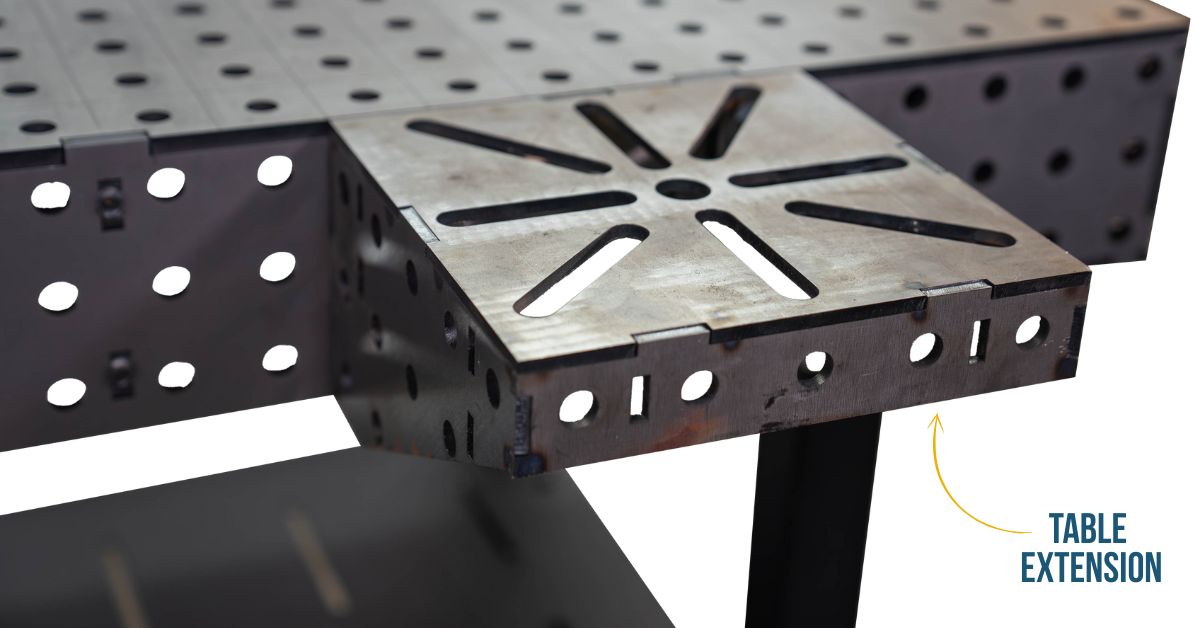

No two programs look alike. Some schools need compact tables to fit smaller labs, while others benefit from linking multiple fixture tables to create larger workstations.

The best tables are designed with flexibility in mind. Locking casters allow instructors to roll and reposition tables for different lessons, then lock them securely in place. Modular add-ons, like table extensions and risers found in our Advanced Welding Table Fixture Kit, expand the work surface, so schools can expand their lab without starting over. This adaptability is especially valuable as enrollment shifts or programs expand their course offerings.

5. Clamping & Fixturing Options

This is the defining feature of fixture tables. The standardized 16mm hole grid turns the table from a simple surface into a complete welding training system.

With a basic student kit, students can learn core skills like squaring, aligning and clamping materials in place. As students advance, expanded kits add risers, side clamps and stops that replicate the setups they’ll encounter in real shops. This hands-on training makes students comfortable with industry-standard processes before they ever step into the workforce – and it’s just one of the many benefits of using welding fixture tool kits in CTE programs.

6. Safety

Safety matters just as much as function in a classroom. A securely clamped project isn’t less likely to slip, tip or cause accidents. Fixture tables help eliminate improvisation with edge clamps or unsafe setups.

Adding locking casters gives instructors mobility without risk. Tables can be shifted for cleaning, rearranged for demonstrations, or grouped for projects, then locked firmly into place during use. The combination of stability and flexibility creates a safer, more controlled environment for students to learn in.

7. Budget & Long-Term Value

Budgets are tight in education, but a well-designed fixture table system is an investment that pays off over time.

With our core welding shop solution, schools can start small and expand gradually as enrollment and funding increase. The scalability comes from design: our Welding Fixture Tables use industry-standard 16 mm holes, a grid layout and modular frames. That means new tables can be connected to existing ones, creating larger work areas, and every clamp, stop and accessory remains compatible. Schools can start small, then add more tables and tools as enrollment grows, without replacing what they already own.

Start Designing Your Welding Program

Tables may not get the spotlight in a welding lab, but they quietly shape every skill a student develops. The right table keeps instruction consistent, builds student confidence and gives schools room to expand. When it comes down to it, it’s where workforce training begins.

If you’re in the early planning stage, check out our blog on welding lab must-haves – it covers the essentials every program should consider before building.

Want to see how our welding fixture tables, fabrication tables and fixture kits can be combined into a flexible system for your program? Access our Core Welding Shop Solutions Brochure by filling out the form below.