Employers expect more than clean welds. They expect professionals who know how to prepare their work the right way from the start. That means knowing how to use welding fixtures.

Welding fixtures are clamps, stops, risers, mounts and other tools designed to secure materials directly to a Welding Fixture Table. This setup ensures every weld begins square, stable and consistent — just as it would in a professional shop. In Career & Technical Education (CTE), they bring those same standards into the classroom.

By introducing fixture kits, programs give students the structure to practice welding the way it’s done in industry, while giving instructors reliable tools to keep lessons efficient and focused on skill development.

The Benefits of Welding Fixtures

1. Stronger Weld Quality

Welding fixtures provide a stable foundation for every project. With parts held square and secure, students can focus on technique (rather than their project moving) and produce consistent, professional-quality welds.

2. A Safer Learning Environment

When parts are clamped down with welding fixtures, students don’t have to worry about slipping materials or unstable projects. It also reduces the risk of burns, torch mishaps or damaged workpieces. Plus, it teaches students that safe setups are an important part of the welding process.

3. More Impactful Teaching

Instructors know that class time is always limited. Without welding fixtures, too much of the time can be spent correcting preventable mistakes. Fixture tool kits reduce those interruptions, allowing teachers to instead focus on demonstrating techniques and helping students progress faster.

4. Efficient Use of Materials & Time

Every crooked weld or misaligned joint often means starting over – and that costs both materials and class time. With fixture tools, projects start out square and stay secure, which means fewer do-overs and smoother progress. Programs see more value from the same resources, stretching budgets further while helping students achieve better results.

5. Career-Ready Skills

Fixturing is standard practice in every professional shop because it sets the stage for accuracy, efficiency and safety. When students learn with welding fixtures, they also build habits employers value: planning setups, checking alignment and adapting tools to different projects.

The results speak for themselves — one CTE welding graduate stepped into a full-time welding job the Monday after graduation, crediting hands-on training for making him workforce-ready.

By practicing with the same fixture systems used in industry, students graduate with the confidence and skills to contribute from day one.

Fixturing Kits for Different Learning Levels

Every program is different, which is why our fixture tool kits are offered in two curated sets that support students at different stages of learning.

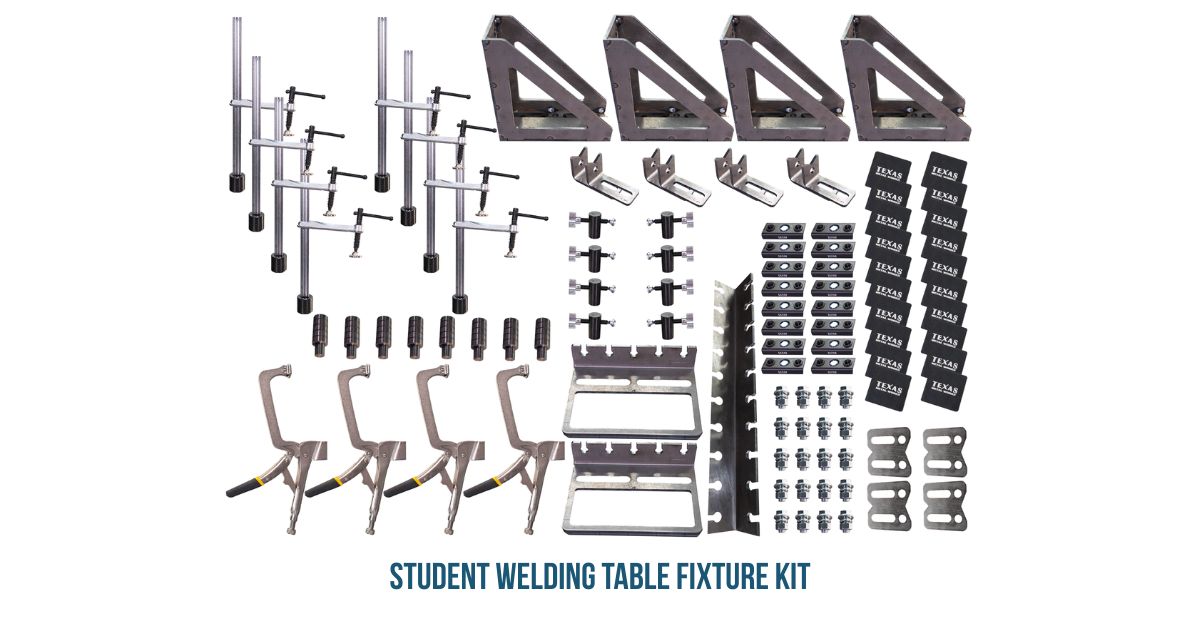

Student Kit (103 pieces)

The Student Fixture Tool Kit is built for introductory welding courses where students are learning the fundamentals. It includes a core set of clamps, stops and other setup tools that help instructors teach the basics of squaring joints, preventing movement and understanding alignment. With these tools, students can:

- Practice building consistent setups for simple joints and assemblies.

- See firsthand how proper preparation leads to cleaner, more successful welds.

- Develop habits of accuracy and repeatability that will stay with them as they progress.

Learn more about the tools included in our Student Fixture Kit.

Advanced Kit (147 pieces)

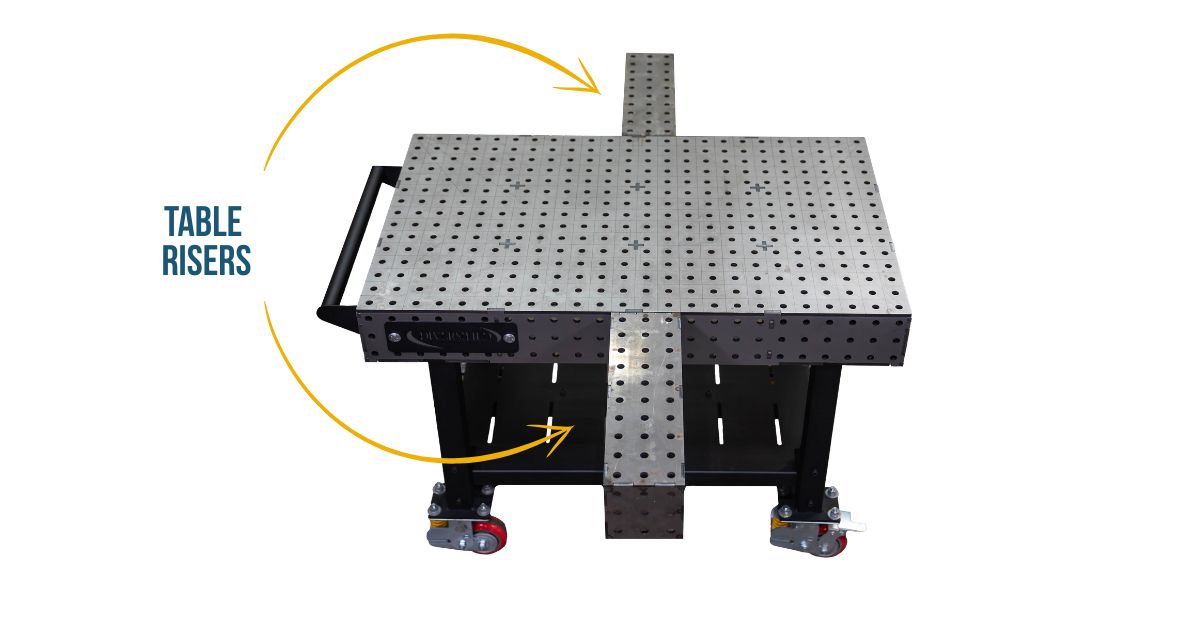

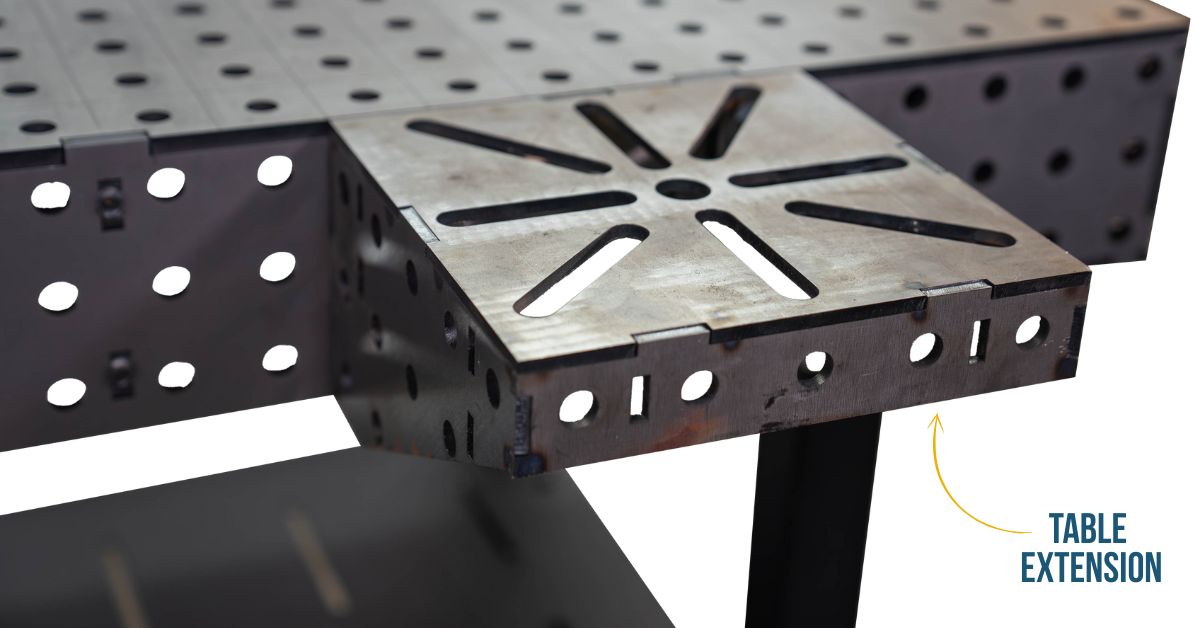

As students build confidence, the Advanced Fixture Tool Kit adds more complexity and flexibility. With risers, mounts, lifting hooks and expanded clamping options, students can create projects that mirror professional shop work. With these tools, students can:

- Tackle larger or multipart assemblies that require more planning and precision.

- Work with angled joints and more complex geometries that demand problem-solving.

- Expand their setups with extensions and risers as projects become more advanced, just as they’ll need to in the industry.

For advanced courses, this kit prepares students for the real-world challenges of welding beyond the basics. Learn more about the tools included in our Advanced Fixture Kit.

The best part? All the tools in each kit are sized for industry-standard 16mm (5/8”) holes, making them compatible with a wide range of fixture tables.

Preparing Students for Careers

The goal of every CTE welding program is to prepare students for the workforce. Welding fixtures support this goal by teaching more than just welding technique – they also teach professional setup practices that make strong welds possible.

When every project starts square and secure, students build skills faster, develop safe habits and leave the program with the kind of experience employers expect on day one.

Check out our Fixturing Tool Kits to explore which one is the best fit for your program.